The reason is simple: products are getting smaller. Nowadays, countless electronic devices such as smartphones, tablets, and blood glucose detectors have increasingly strict requirements for size and are becoming more compact internally, leaving little space for connectors. This trend also appears in the fields of national defense and aerospace, such as in satellites, guided missiles, and avionics systems, where compactness requirements can only be met by "miniaturized" connectors.

The demand for smaller connectors is constantly increasing, and design engineers are facing a series of new challenges. They can no longer complete the design of connectors in the final stage of the project. Micro connectors require careful consideration. It requires designers to consider various factors such as packaging, durability, current load capacity, and replaceability in advance.

Designers should consider the ease of replacement, especially in enclosed enclosures. Molex VITA 67 is an easy to replace miniature connector.

Here are some design suggestions from micro connector suppliers. These suggestions not only come from experts in connector design, but also from the painful experience summary of designers, so they are worth considering for designers.

Considerations for connectors when designing circuits

1. Consider connectors in the early stages of design

Engineers often focus too much on designing the overall system and consider connectors in the final stage of design, "said Mitch Storry, head of product development engineering at TE Connectivity." They think connectors are simple, so they can put related designs in the final stage. Then they get stuck with their own designs

Storry has seen too many stories of designers hastily designing connectors in the final stages of design. He told us that in many cases, designers have to choose non-standard connectors to complete their designs, which not only increases costs but also delays delivery times.

To avoid such problems, experts suggest that the connectors you will use should be considered in the early stages of design, and design space should be reserved for them. The design should also revolve around them.

No one has a reason to listen to you say, 'First, decide which connector you need,' "said Stephen T. Morley, a product development engineer at TE Connectivity." But if they really do that, it can actually save them a lot of time and a lot of trouble

2. Understand the limitations of space clearly

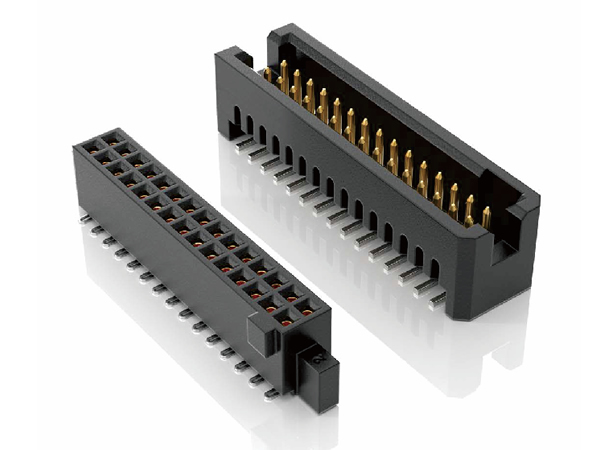

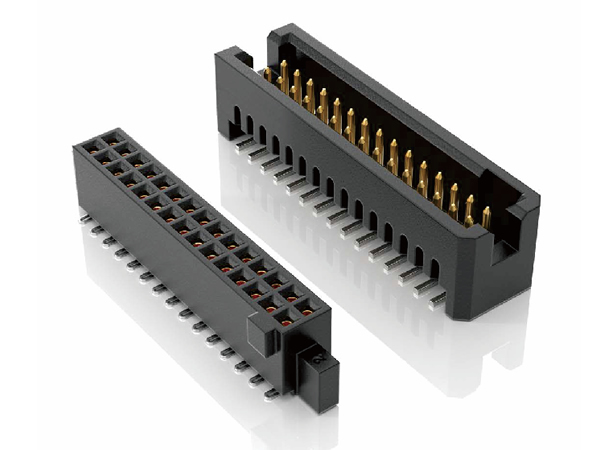

Although the thickness of miniature board to board connectors is typically less than 1 millimeter, they are also commonly used in tightly packaged applications. To address potential packaging issues, designers need to consider the wiring on the PCB board and the additional wires connected to the connectors. Because the spacing has become smaller, you must make the routing and wires narrower

Additionally, please note that some connectors (such as flexible cable connectors) offer options for flipping forward and backward. When designing a system, you need to consider these flipping methods. For example, if there is another component on the front and back of a connector that flips backwards, it may be difficult to access.

Finally, designers also need to be aware that surface mount equipment may not be able to handle smaller components at times. In some cases, they need new vacuum nozzles to solve these problems.

3. Understand the current load capacity

As the size of the connector decreases, the current load capacity of the connector also decreases. Generally speaking, micro connectors can handle currents between 200mA and 500mA, which is about half of the rated current of larger board to board connectors. To compensate for the problems caused by lower current carrying capacity, designers may need to increase the number of terminals.

4. Consider the stability of small/micro connections

I need to suggest this, not only during the design phase, but also during the assembly process, to ensure that they are not damaged, "said Morley from TE Connectivity.

Morley is a micro connector design expert in RF applications, recalling that in his military and space applications, half of the connectors were destroyed during the testing phase.

If we don't take this issue to heart first, it may push up costs, "he said. Damaged connectors require reconfiguration, repair, and labeling. Even more expensive, on-site replaceable connectors may be needed to replace them, and such changes may extend the design time by another one to two weeks.

Morley said, "It should be noted that existing connectors should always be given priority. If these connectors are not compatible with your design, then consider designing your own, which can save you a lot of time

5. Consider ease of replacement

If the appearance of the product is enclosed, then you need a connector that can be replaced from the outside. Otherwise, you will need to do some welding work.

Morley said, "The more you do, the more proficient you become in skills such as welding, but the higher the risk of damage to the entire system

6. Understand the functional requirements of the connector

Suppliers need customers to fully express their needs, otherwise they may misunderstand their needs. This is particularly important when it comes to manufacturing custom connectors.

Accurately clarifying the requirements for connectors is crucial, "Storry said." If the description is unclear or omitted, we may overlook the key requirements of the design

7. Consider mechanical stress

Temperature, shock, and vibration can all generate stress between interfaces and circuits. Experts suggest that you should choose connectors that can avoid the effects of these forces.

I have seen broken solder joints on some PCB boards, "Morley said." When the connector is firmly connected to the board or external structure, it must be able to withstand the forces caused by impact and vibration, otherwise cracks may appear

Morley suggests that engineers use interconnect systems to minimize accumulated stress between installation structures and connection points. Many suppliers offer such systems, "he said," and designers should pay close attention to this